Three Phase Squirrel Cage Induction Motor

In order to understand the speed control, theory and methods, It is important that the basic theory of the controlled component i.e. the motor is understood. The Squirrel Cage induction motor is the most commonly used motor in industry. It is low cost and requires low maintenance in comparison with other motor types. It converts electrical energy into mechanical energy and it is used to provide motion. The conversion process is electro-magnetic induction. Hence the name induction motor

Stator / Rotor electro-magnetic field interaction

Squirrel Cage!

Cause of Rotation:-

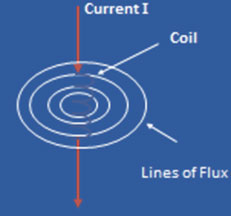

The Supply voltage in each Stator winding produces currents to flow and create a magnetic field hence flux. Flux is a phenomenon of current carrying conductors in a magnetic field.

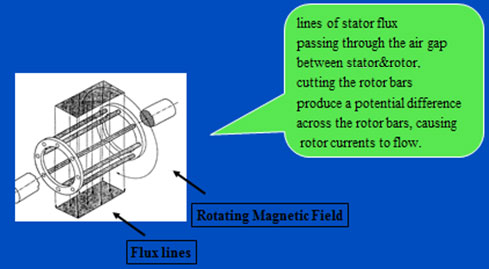

Due to the alternating ( changing direction) nature of the AC supply a rotating magnetic field (flux) is produced. The direction of this rotating magnetic field (flux) can be changed by changing the direction of the stator voltage.

The stator rotating flux induces currents that flow in the rotor bars which produces a rotating magnetic field in the rotor.

The interaction of stator magnetic field and the induced rotor magnetic field produces an electro- magnetic force that causes the rotor to rotate in the same direction as the stator magnetic field.